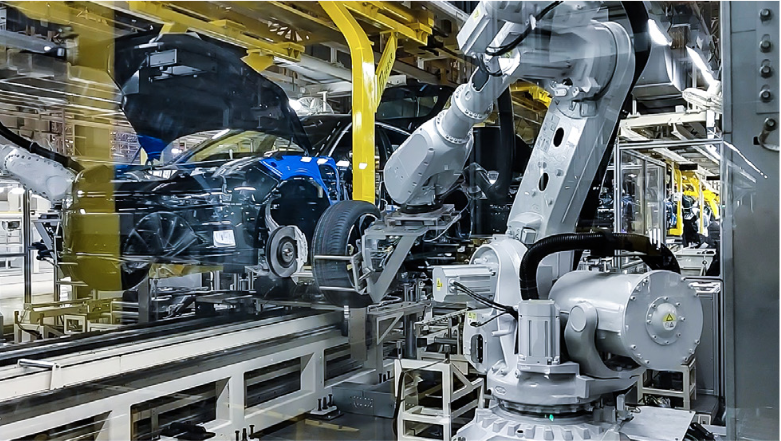

Factory automation is changing how businesses operate worldwide. By using technology to automate tasks that were once done manually, companies can increase their efficiency, reduce errors, and save money.

Many businesses, especially in manufacturing, have seen great improvements from adding automation to their production lines. This article will explain five key benefits of factory automation for your business.

1. Increased Efficiency

One of the most important benefits of factory automation is the increase in efficiency. Machines and robots work faster than people in many cases. They can operate around the clock without needing breaks, which means more work gets done in less time.

For example, automated systems can move materials from one part of the factory to another, or even assemble parts, much faster than human workers. This not only speeds up production but also helps companies meet the demands of customers quicker.

2. Reduced Labor Costs

Another major benefit of factory automation is the reduction in labor costs. While it is true that automation may require an initial investment, the long-term savings are significant. Machines and robots do not need to be paid salaries, receive benefits, or take sick days.

This means companies spend less money on wages over time. By replacing manual labor with automated systems, businesses can allocate their resources more efficiently. In some cases, workers can be reassigned to higher-skilled tasks, improving their productivity and job satisfaction.

3. Improved Quality Control

Factory automation also plays a huge role in improving product quality. Automated systems follow exact instructions, ensuring that each product is made with the same precision every time. Unlike human workers, who might get tired or distracted, machines stay focused and perform tasks consistently.

This leads to fewer mistakes, which means fewer defective products. As a result, businesses can maintain a higher standard of quality, which is crucial for customer satisfaction and brand reputation. Automation also helps in reducing the chances of errors during assembly, painting, or packaging.

4. Enhanced Safety

Safety is always a concern in manufacturing, and automation can help address this. Many factory jobs involve working with dangerous machinery, chemicals, or high temperatures. By automating these tasks, businesses can remove workers from potentially harmful environments.

For instance, robots can handle tasks such as lifting heavy objects or working in high-risk areas where there is a risk of injury. As a result, the number of workplace accidents is reduced. This not only keeps employees safe but also helps businesses avoid costly accidents and workers’ compensation claims.

5. Greater Flexibility

Lastly, factory automation offers greater flexibility in production. Automated systems can be easily reprogrammed to handle different tasks or produce different products. This allows businesses to adjust to changes in demand or customer preferences.

For example, if a company needs to switch from making one type of product to another, they can reconfigure their automated machines with minimal downtime. This flexibility helps businesses stay competitive in an ever-changing market.

Conclusion

In conclusion, factory automation offers several benefits that can significantly improve the way businesses operate. From increasing efficiency and reducing labor costs to improving product quality and safety, automation helps companies grow and stay competitive.

As technology continues to advance, more businesses are finding ways to integrate automation into their operations. If you are looking to improve your business’s productivity and profitability, factory automation is a step in the right direction.